PARYLENE COATING SYSTEM OPTIONS

Paratronix® Vapor Phase Adhesion Promotion System

This process is performed prior to Parylene coating. Parts are exposed to a coupling agent after being loaded into the coating machine.

The same coupling agent used in the liquid promotion process is introduced directly into the coating chamber via a small auxiliary port. This reservoir is then heated to a temperature at which the coupling agent vaporizes. The now gaseous coupling agent deposits on the substrate. This deposition occurs prior to the coating process. Coating starts immediately after the complete vaporization of Silane.

Additional Options:

- Custom chamber extension

- Custom chamber sizes

- Vacuum leak test kit

- UPS Battery back up

- Full stock room of spare parts

Additional Services:

- On-site troubleshooting

- System training

- Process development

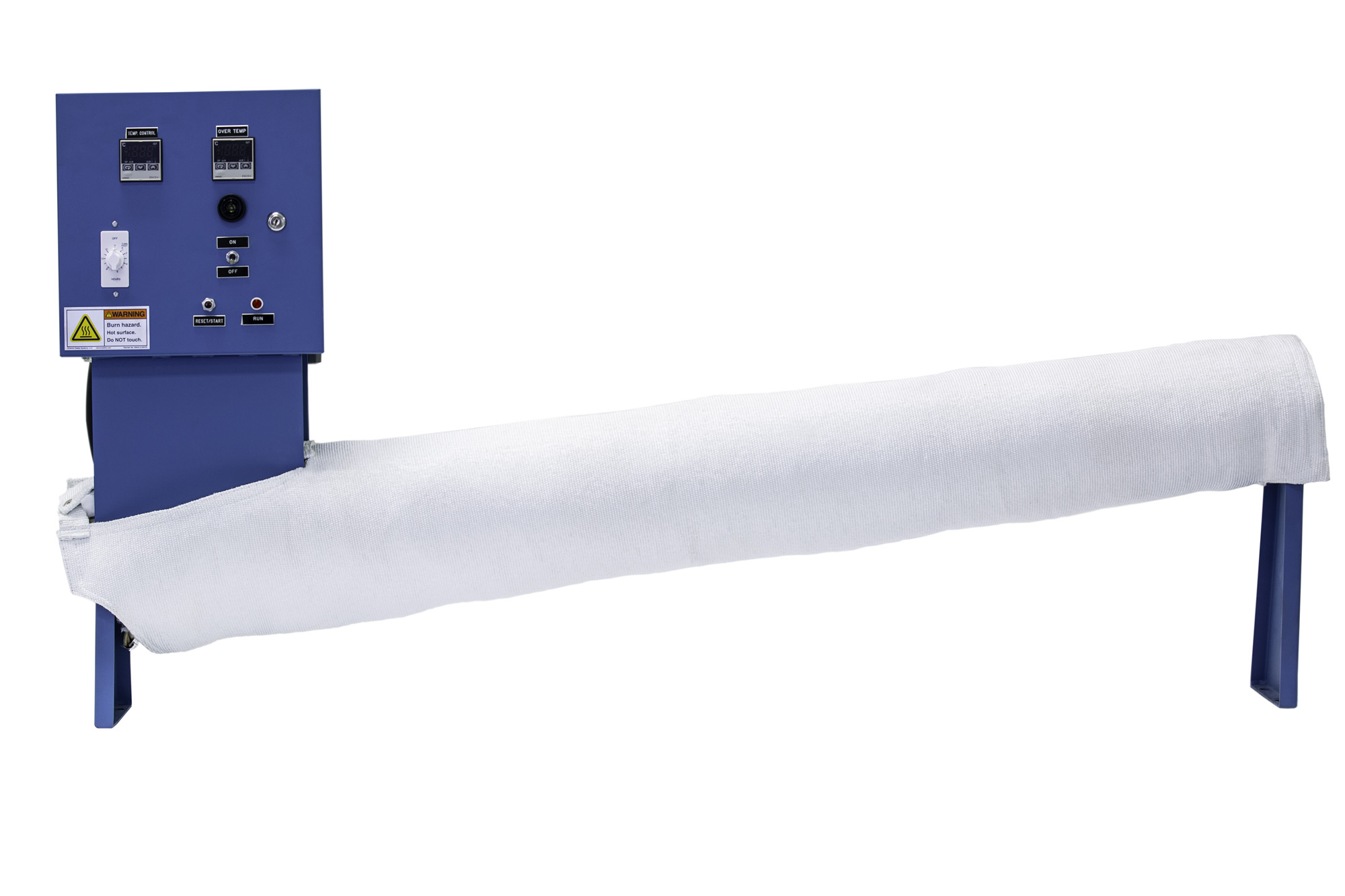

Paratronix® Burn-Out Furnace

The Paratronix® Burn-out Furnace is used to clean residual Parylene build up out the Quartz Pyrolysis tube.

Please inquire for further technical specifications and custom requests.