THE PARYLENE CONFORMAL COATING PROCESS

Introduction to Parylene Coatings

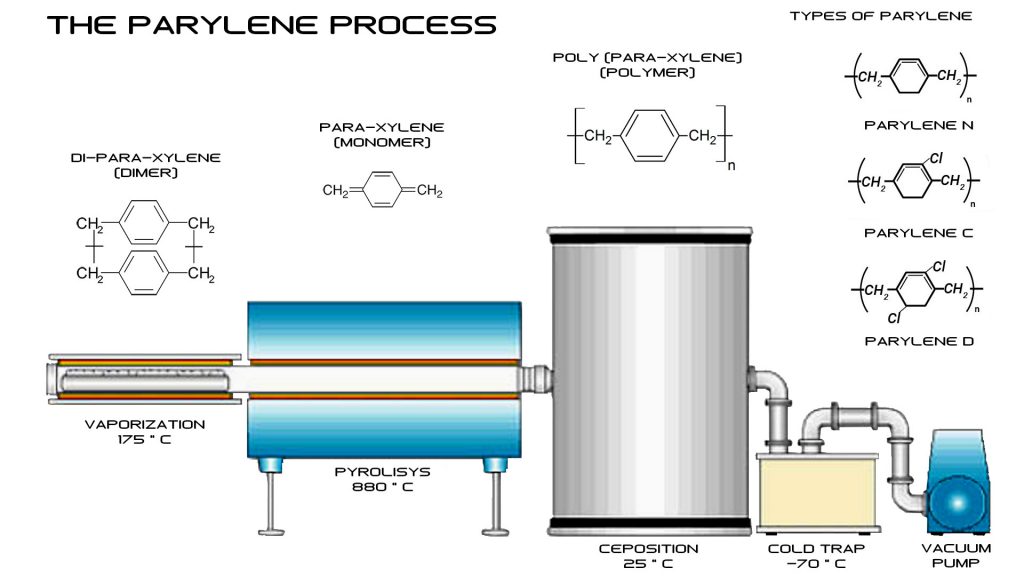

Parylene is a unique class of vacuum-deposited polymers that produce high-quality, pinhole-free, conformal coatings. There are several types of Parylene polymers, including Parylene N, Parylene C, and Parylene D, each with its own set of material attributes. These coatings offer exceptional adhesion to most substrates and provide superior chemical and corrosion resistance. Parylene polymers also boast high dielectric strength, extremely low permeability to moisture and gases, high temperature and UV stability, and biocompatibility. These characteristics make Parylene the preferred coating material for various medical, aerospace, military, and industrial applications.

The Parylene Coating Process: Step by Step

Preparation and Weighing

The Parylene coating process begins with the preparation of granular dimer, which is weighed to achieve the desired coating film thickness. Accurate weighing is crucial to ensure the consistency and quality of the final coating.

Sublimation and Pyrolysis

Once weighed, the granular dimer is heated under vacuum to convert it from a solid to a gaseous state. This step is known as sublimation. The gas then undergoes pyrolysis at a higher temperature, breaking the dimer into a monomeric gas. This transformation is essential for the next stage of the process.

Deposition

The monomeric gas is drawn into the coating chamber, which is maintained at ambient temperature. Here, the monomer gas is vacuum deposited onto the substrate surface. Since Parylene is applied in a gas phase, it provides exceptionally conformal coatings on all unmasked surfaces, including intricate surface crevices, far beyond the capabilities of other conformal coating processes such as dip or spray coatings.

Benefits of Parylene Coatings

Exceptional Adhesion and Protection

Parylene coatings adhere excellently to most substrates, offering unparalleled protection against chemicals and corrosion. This makes them ideal for applications where durability and reliability are paramount.

High Dielectric Strength and Low Permeability

With high dielectric strength and extremely low permeability to moisture and gases, Parylene coatings are perfect for electronic components and sensitive equipment that require insulation and protection from environmental factors.

Temperature and UV Stability

Parylene polymers exhibit high stability under extreme temperatures and UV exposure. This property ensures long-lasting performance, even in harsh conditions.

Biocompatibility

The biocompatible nature of Parylene makes it suitable for medical applications, including implants and devices that come into contact with bodily fluids and tissues.